PASSIVE FIRE PROTECTION

Home / Passive Fire Protection

Passive Fire Protection :

- Fire Rated Cable Coating – Circuit Integrity 90 minutes 750/1100 Deg C

- Fire Rated Mortar – Upto 4 hours Fire rating

- FP Panel – Upto 4 hours Fire rating

- Acoustic Acrylic Sealant – Upto 4 hours Fire rating

- Coating for protection of pollution flashover on High Voltage Insulator

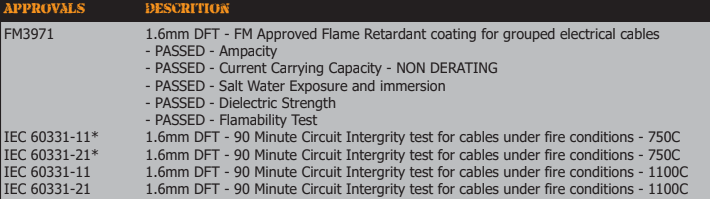

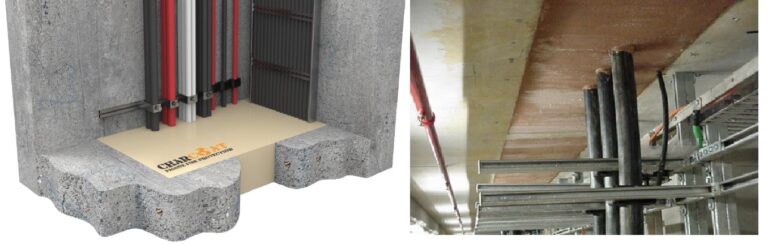

CABLE COATING :

CharCoat Cable Coating is the intumescent Latex Coating for the Fire Rating of Electrical Cables (Circuit Integrity) and to stop flame Spread :

- Intumescent Water based Coating

- Impermeable according to FM3971

- Classified for up to 90 min. Fire Rating 750C Cellulosic Fire.

- Classified for up to 90 min. Fire Rating 1100C Hydrocarbon Fire.

- Low DFT (Dry Film Thickness) of 1.6mm

- 100% UV Stable Non-Corrosive

- Non-Toxic, Non-Hazardous

- Rodent Proof Certificate (Gnawing Certificate)

- 600-700% typical Intumescent expansion after 10 minutes of exposure to 870°C

- Zero maintenance required

- Suitable: Sub-station, Cable Ducts, Transformers Bays, Switch Rooms, Marine Applications

FIRE RATED MORTAR – UPTO 4 HRS. FIRE RATING :

- Up to 4 hours with single cable and tray

- Up to 4 hours E Ratings (Integrity)

- Up to 4 hours EI Ratings (Integrity & Insulation)

- 50mm to 100mm thick seals

- Easy install with Rockwool backing

- Expands on cure to seal around cable

- No Sealants required

- Load bearing

- EN1366 tested & Approved

- CE Mark and UL

INSULATOR COATINGS :

CharCoat IC is the Vulcanized silicone Coating on the market today for the protection of Insulators from pollutants :

- Protects from pollutants and contaminating layers

- Prevents dry band layers

- Prevents partial discharge and flashover

- Improved performance due to lack of pollutants

- Stops UV, ozone and ageing degradation

Properties :

- Low DFT of 0.3 – 0.5mm

- Adhesion to glass, ceramic & resins

- BS2918 – Dielectric Strength – 64kV/mm

- IEC 93 – Surface & Volume Resistivity

- IEC 60273 – Hydrophobicity

- ASTM D 495-99 – Arc Resistance

- ASTM D 2303-97 – Tracking & Erosion

- CPRI REC Spec – Hydrophobicity recovery after 100 hours Flash over Arc test

- 100% UV Proof